Published on Apr 02, 2024

In a Ready Mix Concrete (R M C) batching plant, there are two units.

1. Mixing unit

2. Delivery unit

The transit mixer and concrete pumps are the delivery units of a RMC plant. The transit mixer used to deliver the RMC of same workability and quality at work site and the concrete pump is used to deliver the RMC at the desired place as per requirements. Before discussing about Transit mixer and concrete pump, must discuss about the significance of RMC

The mechanisms of deterioration of concrete due to various physical, chemical, biological and environmental pollutants are widely researched. In search of possible reasons of non performance of concrete on the face of such voluminous researched. It is necessary to recognize the interactive nature of various factors such as there is interaction between various aggressiveness temperature and humidity as well as the nature of resultant concrete, e.g. PH value, chloride bounding, electrical resistivity etc. The distress to concrete structures is quiet often due to non adherence to the requirements of specifications.

The areas a of non compliance not only related to the appropriateness of ingredients of concrete , adequacy of mix properties, but also to workmanship-notably placing, compaction and curing of concrete. Specifications are often difficult to check on site. That results in difficulties is ensuring compliances of specifications and certainty regarding quality achieved. RMC can play a significant role in ensuring quality and durability of concrete that goes in to the structures.

RMC is a revolutionary product, which metamorphosed the entire construction industry. It is a factory made, quality product produced by skilled persons with the help of advanced state-of-the art of technology.

The advanced state-of-the art of technology means play of machineries for the fruitful production of RMC. The RMC plant mixer should always computerized. Here only deals about the transit mixer and concrete pump - the delivery units of RMC-.

Transit mixer that ensure timely delivery of concrete of same workability and quality at the work site.

The concrete pump is used to deliver the concrete at the desired place as per requirements.

The name itself gives a picture of the machine. Basically it is a vehicle with a rotating mixing drum. The drum is rotating during the traveling of the vehicle to the work site. This rotation of the mixer drum ensures the concrete of same workability and quality. Transit mixer used only in RMC plants and which timely deliver the concrete to the work site.

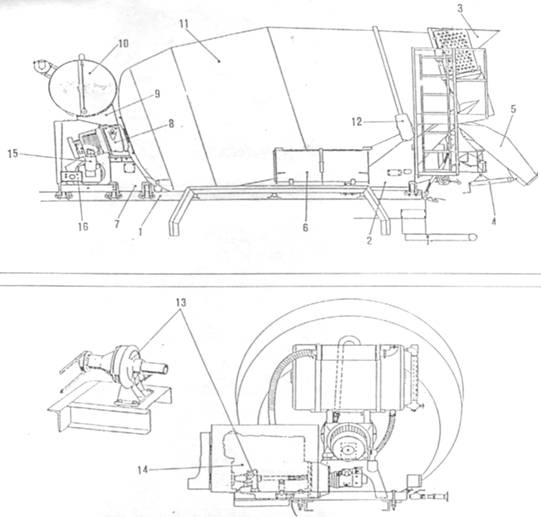

1. Auxiliary frame.

2. Discharge support.

3. Detachable feed hopper.

4. Crank chute support.

5. Swiveling discharge chute.

6. Additional extension chute.

7. Bearing pedestals.

8. Drum bearing.

9. Water tank support.

10. Water tank.

11. Mixing drum.

12. Rollers.

13. Water pump.

14. Diesel engine.

15. Suction filter

16. Control cabinet.

The supporting element of the mixer is the auxiliary frame to which the discharge support with the discharge support with discharge channel is mounted with U-bolts. The dischargeable feed hopper is mounted to the discharge support by means of a tubular frame.

The swiveling discharge chute can be adjusted vertically by a crank chute support. It has an elliptical cross-section and is mounted to the discharge support by a reinforced double arm. The discharge chute can be extended with additional extension chute.

The gear box with drum bearing is bolted to the bearing pedestal which is fixed on the auxiliary frame with U-bolts. The water tank support with water tank mounted to the gear box.

The mixing drum with mixing spirals made of highly wear resistant steel is supported by two rollers in discharge support. The water pump is directly flanged to the gear box. At a mixing drum speed of 14 /min ,the water pump reaches a pressure of 3.5 bars, and supplied 250 l water per minute in ‘mixing’sence of rotation.

The mixer is driven by a separate diesel engine via a hydrostatic axial piston gearbox allowing infinitely variable mixing drum speed of 0-14 per minute in either direction. The diesel engine is started at the control cabinet, which also in corporate operating hours meter and temperature gauges.

The mixing drum is driven by a separate diesel engine via a hydrostatic axial piston. Gear box allowing infinitely variable mixing drum speed of 0-14/min in either direction. The mixing spirals in the mixing drum is right hand helical. The clock wise rotation of the mixer Keeps the concrete at the bottom of the mixer drum and ensure the correction mixing with correct composition of concrete. During the traveling of the mixer, the drum should rotate in clockwise direction. At the time of pumping, the drum should rotate in anticlockwise direction, due to the sense of rotation the concrete come out from the drum to the swiveling discharge chute.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |